With technological advancements and the volatility of global fuel prices, battery powered generators are on the rise.

How a hybrid generator can be incorporated into your next project, along with its top four benefits.

To include real numbers in the blog, we will also look at the benefits in relation to a Power Electrics case study.

THE GREEN FACTOR

The most common and reliable way is a diesel generator with an integrated lipo4 battery.

Similar to a hybrid car, the generator primarily acts as a battery charger or power source when demand is greater, greatly reducing the need for the diesel generator to run.

By reducing the running time of the engine, the emissions from the generator are reduced by up to 90%.

Hybrid generators can also be combined with renewable sources such as solar or wind to charge the battery.

This could mean that in the summer months or windy days the generator is not needed at all to charge the batteries, further reducing project emissions.

REDUCE FUEL BILLS

Along with the green credentials, a hybrid generator can reduce the amount of fuel used during a project, lowering project fuel bills.

In fact, the engine will run up to 90% less compared to a conventional generator, resulting in huge savings in fuel, logistics and maintenance costs and extending the life of the hybrid generator set.

The generator’s engine was only needed at certain times of the day to ensure that the lipo4 battery was charged.

MINIMIZE SITE NOISE

The battery is absolutely silent during use.

Although diesel generators have come a long way in terms of acoustic reduction, they still make about 75 dB(A) at 1m, so if noise is critical a hybrid generator solves that problem e.g. in residential areas the security system and garden lights don’t need a running engine at night, because the battery has stored enough power to go through the night.

UNTERRUPTED POWER SUPPLY

In the situation where the power is critical, it is important that there are no interruptions in the grid supply.

With a standby diesel generator, you will go ‘through the darkness’ for a few seconds until the ATS system takes over.

With a hybrid generator, the battery system provides a continuous power supply.

This is important when power is critical, for example computer systems that do not have their own uninterruptible power supply (UPS).

In summary, hybrid generators can provide reliable power that is emission-friendly, reduce fuel bills, minimize on-site noise, and provide uninterrupted power.

HOW IT WORKS?

Telecommunications operators around the world face significant challenges in powering mobile base station (BTS) sites in remote areas.

In many cases, the locations are simply too far or too unreliable from the AC grid to be economical on the AC grid.

These sites are often powered by small diesel generator sets that run continuously.

Sealed lead-acid batteries (VRLA) provide backup power for generator maintenance, start-up, and cover the occasional case when fuel runs out.

The ongoing charges are high and include:

• Direct fuel costs

• Truck rolls. Refueling is usually required every once a week, at great expense due to a very remote location.

• Generator maintenance.

• Replace generator. With continuous use, a small generator can last only two years.

By switching to a hybrid power unit, an operator can realize significant savings in operating costs.

So the generator only runs part of the time and the battery keeps the load running while the generator is off.

In the conventional diesel powered system, the generator has capacity to run the load and charge the battery.

To ensure a reasonable charging time, the generator must be much larger than the load.

But usually the generator only feeds the load, running anywhere from 30% to 60% of the maximum load.

The hybrid system changes this so that the generator is always running at near full load. How? It only works to charge the batteries. Once the batteries are charged, it will stop.

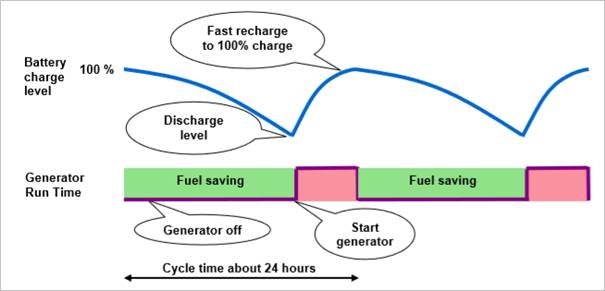

• The system starts with a fully charged battery.

• The generator is switched off and the battery takes over the load.

• Once the battery has been discharged to a certain level, the generator restarts and rapidly charges the battery.

• The generator shuts off again and the cycle repeats.

Usually the generator will run about 10 to 20% of the time.

For the rest of the time, the battery drains.

A full cycle can take about a day, depending on the characteristics of the load and how the operation has been optimized. More on this later.

Where are the savings

Direct fuel costs.

Consider this example:

A 15 kVA generator in 24/24/7 operation at 40% load.

Takes 1.5 liters per hour or 252 liters per week. Change to hybrid operation at 80% load, 20% duty cycle.

Then the fuel consumption is 2.65 liters per hour, or 89 liters per week at 20% duty cycle.

This gives a fuel saving of 65%.

Extra fuel costs.

In addition to the lower fuel consumption, there will also be a corresponding reduction in the number of truck rolls for refueling.

For remote locations, the cost of getting fuel to a location is likely to be higher than the direct cost of fuel.

Generator maintenance interval.

Instead of running at moderate load 100% of the time, the generator will run at full load 20% of the time or less.

The generator service interval is based on running time (not load), so the service interval is now at least 4 times longer.

This ensures direct savings on truck rolls.

The life of the generator is extended in the same way, so replacement costs are much lower.

Batteries

Compare to VRLA batteries, our lipo4 batteries are rated for at least 5000 deep cycles.

In practice, a depth of discharge of 80% means that the deeper the discharge, the longer the system runs on the battery and the greater the fuel savings.

The BMS (Battery Management System) automatically connects to the UPS/Inverter for accurate charging.

The BMS + UPS must accurately manage the charge and discharge cycles, including charge voltage, charge duration, charge rate and depth of discharge.

Discharge accurately integrates the current being discharged by the battery over time to give a total discharge in amp hours for the discharge/charge cycle.

When it reaches the planned depth of discharge (20%), the UPS closes a contact to start the motor.

With a well-controlled temperature and a good cyclic rating, we can expect a service life of 10 years or more.

This should be factored into the calculated savings as part of the total cost.

Optimization

Depth of discharge.

Adjust the depth of discharge to balance battery life with time running on batteries.

The deeper the discharge, the longer the system runs on the battery and the greater the fuel savings.

Monitoring.

Remote management allows the network operator or service organization to demonstrate hybrid cost savings, ensure optimal operation, manage response to faults, and support battery warranty claims.

This information must be available remotely.

Networked applications

Hybrid technology can deliver even greater savings if AC power is available.

The batteries can then be used to “drive” through an AC fault without the need to start the engine.

The engine only needs to be started during longer AC failures.

Fuel savings depend on the frequency and duration of AC outages.

In theory, if all failures are shorter than the battery backup time, the fuel savings will be 100%.

This is of course unlikely, but savings of more than 50% are likely.

If you have any questions, don’t hesitate to contact us.

What can we do for you?

If you are looking for the alternative with an unprecedented price/quality ratio.

Then we may be your new point of contact, we are ready, are you?